SQUARE BOTTOM PAPER BAG MACHINE WITH TWO PLY

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Classification:

Keyword:

SQUARE BOTTOM PAPER BAG MACHINE WITH TWO PLY

E-mail: sales@wzruizhi.com

- 产品描述

- Parameter

- Configuration

- Details

- Sample Bag

- Video

-

- Commodity name: SQUARE BOTTOM PAPER BAG MACHINE WITH TWO PLY

- Commodity ID: RZFD-330/450(2 PLY)

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Key words:- SQUARE BOTTOM PAPER BAG MACHINE WITH TWO PLY

-

Model

RZFD-330

RZFD-450

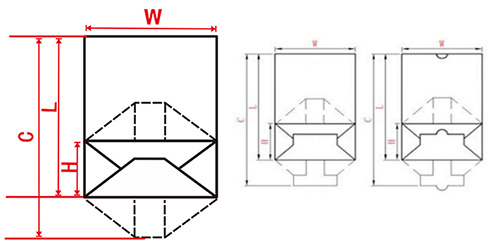

Cutting length C

270-530mm

270-530mm

Paper bag width W

120-330mm

220-450mm

Paper bag bottom width H

70-180mm

90-180mm

Paper thickness

60-140g/m2(total gsm of two ply : 180gsm)

70-140g/m2(total gsm of two ply : 180gsm)

Paper bag speed

30-180 pcs/min

30-140 pcs/min

Paper roll Maximum width

1050mm

1290mm

Roll paper diameter

1200mm

1200mm

Machine power

3phase 4line 380V 15kw

3phase 4line 380V 16kw

Machine weight

7200 kg

7500 kg

Machine size(mm)

9200x3700x2000

9200x3700x2000

Bottom types

-

1.Use France Schneider Touch Screen Human-Computer Interface, operate and control easily.

2.Adopt Germany Original LENZE PC Control, integrated with optical fiber, ensure high speed running steadily.

3. Germany Original LENZE Servo Motor and Germany Original SICK Photoelectric Eye Correction, tracking printing bag accurately.

4.Raw material load adopt Hydraulic pressure up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, Reduce adjustment time.

Name

QTY

Original

Brand

Control System

PC Program Controller

1

Germany

LENZE

Human computer touch screen interface

1

Schneider

FRANCE

Servo Motor

2

Germany

LENZE

Servo Driver

2

Germany

LENZE

Traction Servo Motor

1

Taiwan

DELTA

Servo Driver

1

Taiwan

DELTA

Servo motors for two ply

2

Germany

LENZE

Servo Drivers for two ply

2

Germany

LENZE

Motor Frequency Converter

1

Switzerland

ABB

Positioning Photoelectric Eye

1

Germany

SICK

Low Voltage Electrical Apparatus

1

USA

EATON

Button&Junction Box

1

Germany

Weidmuller

Photoelectric Sensor

1

Switerland

Baumer

Deviation correction and tension control system

EPC Controller

2

Italy

SELECTRA

Servo EPC Motor

2

Italy

SELECTRA

Ultrasonic Sensor

2

Italy

SELECTRA

Magnetic Powder Brake

2

China

WEIZHENG

Transmission

Synchronous Belt

1

China

BELDI

Synchronous Wheel

1

China

MTED

Bearing

1

Germany

FALA

Guide Roller

1

China

BAIXIAO

Gear

1

China

MTED

Roll Pneumatic Shaft

1

China

MTED

Finished Bag Conveyor belt

1

Switzerland

Glue position

Bottom Glue(Paste bottom white latex)

1

China

MTED

The center of the water spraying gun(dense adjust Glue gun )

1

China

MTED

Water White latex

1

China

MTED

-

-

-

Related products

Message

www.mted.com Wenzhou Ruizhi Packing Machinery Co.,Ltd. Powered by www.300.cn Privacy policy

Contact us