RZJD-G250J FLAT BOTTOM PAPER BAG MACHINE

The Machine for reel original colored paper or drum paper printing, such as kraft paper, glossy paper, medical paper roll consists of a paper bag process by puncture, center glue, color code length, raw material into a tube, set off long retreat, bottom fold bottom, bottom glue. Pocket bottom forming, complete finished bag finishing a. The machine operation more convenient, more efficient, more stable is in the production of a variety of different paper bags, fenestration bread bags, leisure food bag, bag of bread, dried fruit bags and so on environmental paper bag paper bag machine equipment.

Classification:

Keyword:

V Bottom paper bag machine

E-mail: sales@wzruizhi.com

- 产品描述

- Parameter

- Configuration

- Details

- Sample Bag

- Video

-

- Commodity name: RZJD-G250J FLAT BOTTOM PAPER BAG MACHINE

- Commodity ID: RZJD-G250J

The Machine for reel original colored paper or drum paper printing, such as kraft paper, glossy paper, medical paper roll consists of a paper bag process by puncture, center glue, color code length, raw material into a tube, set off long retreat, bottom fold bottom, bottom glue. Pocket bottom forming, complete finished bag finishing a. The machine operation more convenient, more efficient, more stable is in the production of a variety of different paper bags, fenestration bread bags, leisure food bag, bag of bread, dried fruit bags and so on environmental paper bag paper bag machine equipment.

Key words:- V Bottom paper bag machine

-

Model

RZJD-G250J

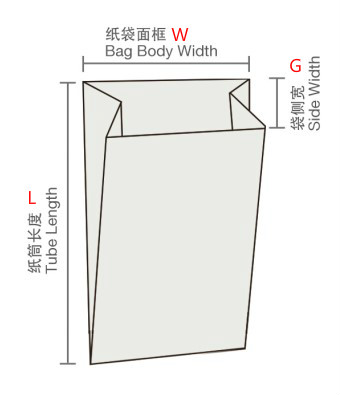

Cutting Length Of Bag C

110-460mm

Bag Length L

100-450mm

Bag Width W

70-250mm

Gusset G

20-120mm

Bag Mouth Height H

15/20mm

Bag Speed

50-500pcs/min or 90 meters/min

Paper Feed Width

100-760mm

Paper Material Diameter

200-1000mm

Paper Material Thickness

35-80g/m²

Rolling Film Width

50-200mm

Film Thickness

0.022-0.035mm(OPP、PET)

Rolling Film Diameter

500mm

Core diameter

76mm

Working Air Current

≥0.12m3/min,0.6-1.2MP

Electric Power

380V3 phase 4 wire 19 kw+5kw(hot melt gluing machine)

Total Weight

4800kg

Machine Dimesion

6800x2300x1900mm

-

1. Using the French SCHNEIDER touch screen man-machine interface, operating at a glance, easy to control.

2 .Using the British TRIO Motion Controller (PC), through the integration with the optical fiber to ensure high-speed operation and stability.

3 .Using the Japanese Original YASKAWA servo motor with the German original SICK photoelectric eye correction, accurate tracking printing bag size.

4 .The raw material loading and unloading adopts the pneumatic cylinder lifting structure, the roll adopts the full automatic constant tension control.

5 .Raw materials China correction using Italy SELECTRA, reduce the roll adjustment time alignment.

Name

Qty

Place of Origin

Brand

Control System

Programmable Logic Controller

1

England

TRIO

Touch Screen

1

France

SCHNEIDER

Servo Motor

3

Japan

YASKAWA

Servo Driver

3

Japan

YASKAWA

Encoder

1

Germany

Posital

Main Motor

2

Taiwan

HOUSIN

Frequency Converter

2

Switzerland

ABB

Photoelectric Eye Color Code Tracking

1

Germany

SICK

Positioning Photoelectric Eye

1

Germany

SICK

Low Voltage Electrical Apparatus

1

USA

EATON

Radio Button

1

China

Pinshuo

Name

Qty

Place

Brand

Transmission

Synchronous Belt

1

China

BELDI

Synchronous Wheel

1

China

MTED

Bearing

1

Germany/Chinese

Fala/Haerbin

Guide Roller

1

China

BAIXIAO

Pneumatic Shaft

1

China

MTED

Name

Qty

Place of Origin

Brand

Glue Position

Bottom Glue (Paste White Latex)

1

Ruizhi

MTED

The Center Of The Water Spraying Gun(Density Adjustable Glue Gun)

1

China

XLG

Water White Latex Pneumatic Glue Barrel

1

Chinese

Name

Qty

Place of Origin

Brand

Deviation Correction / Tension Control System

Edge Control Rectifying Photo-Sensor

1

Italy

SELECTRA

Edge Control Rectifying Motor

1

Italy

SELECTRA

Rectification Module

1

Italy

SELECTRA

Automatic Constant Tension Controller

1

England

TRIO

Tension Magnetic Powder Brake

1

Taiwan

TAIWAN

-

-

-

Related products

Message

www.mted.com Wenzhou Ruizhi Packing Machinery Co.,Ltd. Powered by www.300.cn Privacy policy

Contact us