RZJD-G450J

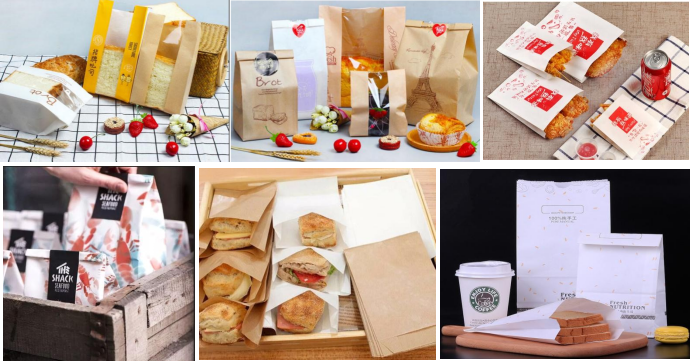

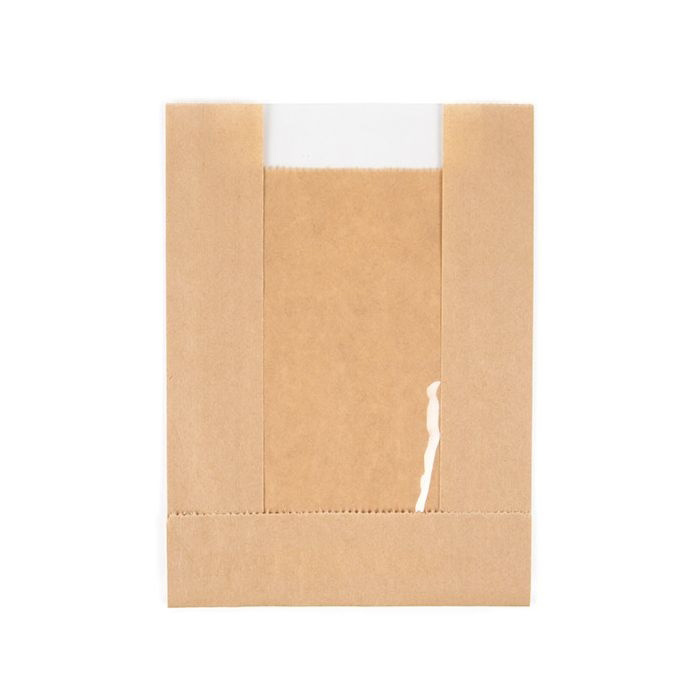

RZJD-G350J Full automatic high speed sharp bottom paper bag making machine is suitable for varied primary and printed rolling paper, such as Kraft paper,slick paper,coated paper,medico paper and so on. It finishes all procession all in a time consisting: perforating, middle gluing,printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collect final product quantitatively. This machine operate easier, working more efficient, and performance more steadily. It is a fantastic machine for full paper bag, paper bag with window, leisure snack bag, bakery bag, fast food bag, dry fruit bag eco-bag and so on.

Classification:

Keyword:

E-mail: sales@wzruizhi.com

- 产品描述

- Parameter

- Configuration

- Details

- Sample Bag

- Video

-

- Commodity name: RZJD-G450J

- Commodity ID: RZJD-G450J

RZJD-G350J Full automatic high speed sharp bottom paper bag making machine is suitable for varied primary and printed rolling paper, such as Kraft paper,slick paper,coated paper,medico paper and so on. It finishes all procession all in a time consisting: perforating, middle gluing,printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collect final product quantitatively. This machine operate easier, working more efficient, and performance more steadily. It is a fantastic machine for full paper bag, paper bag with window, leisure snack bag, bakery bag, fast food bag, dry fruit bag eco-bag and so on.

-

Model

RZJD-G450J

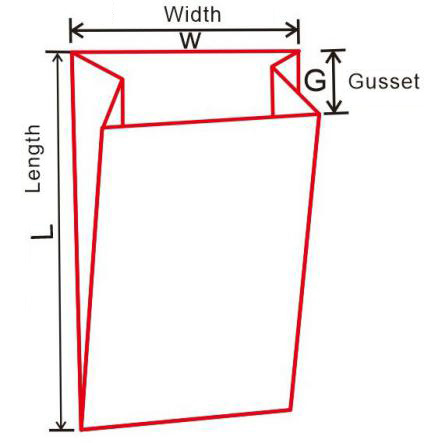

Length of cutting bag

165-715mm

Bag length

160-710mm

Bag width

70-450mm

Insert size

20-120mm

Bag mouth height

15/20mm

Bag speed

50-350pcs/min

Paper feed width

210-1170mm

Paper material diameter

Φ1100mm

Inner diameter of paper

Φ76mm

Paper material thickness

35-80g/m²

Working Air Current

≥0.12m³/,0.5-0.8

More than 0.12m³/ minutes,0.5-0.8MPa

Machine power

380V 3 (phase)4 (wire) 32kw

Total weight

6500kg

Machine Dimesion

6800*2900*2000mm

-

1.Available Germany LENZE human-computer touch screen,it is easy to operate and control.

2.Available Germany LENZE motion controller((PC)), integrated with optical fiber,ensure the machine with high speed steadily.

3.Available GermanyLENZE servo motor integrated with Germany original SICK rectifying photo sensor, ensure the printed paper length under tracking precisely.

4.The loading and unloading of the raw materials adopts the hydraulic automatic lifting structure, and the full automatic tension control is adopted for the reel.

5.Available Italy SELECTRA material edge rectify system, substantially cut off the edge alignment time

Control system

Name

Quantity

Original

Brand

CPU Motion Controller

1

Germany

LENZE

Human-Computer Touch Screen

1

Germany

LENZE

Servo Motor

3

Germany

LENZE

Servo Driver

3

Germany

LENZE

mains filter

1

Germany

LENZE

Main Motor

2

Taiwan

HOUSIN

Frequency Converter

2

Switzerland

ABB

Photoelectric Color Code Tracking Sensor

1

Germany

SICK

Position Photoelectric Track Sensor

1

Germany

SICK

Low-Voltage Appliance

1

US

EATON

Transmission

Name

Quantity

Original

Brand

Synchronous Wheel

1

China

MTED

Synchronous Belt

1

China

BELDI

Interrupting double side synchronous Belt

1

Germany

OPTIBELT

Bearing

1

Germany

FALA

Guiding Roller

1

China

BAIXIAO

Paper Unwinding Air Shaft

2

China

MTED

Keel

3

China

MTED

Gluing device

Name

Quantity

original

Brand

Bottom Gluing Device

1

China

MTED

center-sealing glue gun for

water-based glue

1

China

XLG

Hydrosol white emulsion pneumatic spray gluing tank

1

China

TIANMA

Control system

Name

Quantity

Original

Brand

Edge Control Rectifying Photo-Sensor

1

Italy

SELECTRA

Edge Control Rectifying Motor

1

Italy

SELECTRA

Rectification Module

1

Italy

SELECTRA

Rectification Straight Guiding Rail

1

Taiwan

HIWIN

Magnetic Powder Brake

2

Taiwan

WEIZHENG

hydraulic upper material for unwinding roll

1

Taiwan

AIRTAC

Edge Control Rectifying Photo-Sensor

1

Italy

SELECTRA

Note:The purchased parts used in this machine will be replaced by the same-level brand that is not lower than the existing brand quality when the equipment is upgraded or updated. The seller will reserve the right without further notice.

-

-

Related products

Message

www.mted.com Wenzhou Ruizhi Packing Machinery Co.,Ltd. Powered by www.300.cn Privacy policy

Contact us